Automotive

The percentage of plastics used in the automobile industry is constantly increasing. The aim of this is firstly to cut costs and secondly to reduce the weight. Many of these plastic components have to be joined together. The laser welding of plastics is a technique that has grown enormously within the automobile industry over recent years. Applications range from sensors for controlling various components, and tanks for oil, gasoline, or water, right through to interior or exterior uses.

Tanks in the automobile industry

Liquid Vapor Separator (LVS)

Typical applications for tanks within the automobile industry concern the fuel, oil, and water systems. Leister adapts the welding technique to suit the requirements of the application concerned. The Liquid Vapor Separator (LVS) relies on the GLOBO welding technique. Both the outer edge of the housing and the bars and pillars on the inside are welded onto the cover. However, these have different heights due to the nature of the manufacturing process. With GLOBO optics, these tolerances can be easily bridged and constant pressure can be ensured. Bar height tolerances can also be bridged using the quasi-simultaneous welding technique. All the welded bars are heated almost simultaneously and this results in a melt path. This path can be integrated into the process for quality control purposes. Consequently, the oil filter can be welded so that it is completely tight.

Sensor components in the automotive industry

Electronic package

The lid of the electronic package, which also has a reinforcing function for the circuit board, is joined by means of transmission welding. Despite the black colouring with a special pigment, the lid material is transparent for the laser beam.

The sleeve is welded on to the position sensor itself with a screw-on tag. During the welding process, the pre-assembled part is rotated around the longitudinal axis and radiated from the side with a stationary laser at the height of the weld root face (collar). The result is a strong, gas-tight welding seam.

Interior components

Dashboard / head-up display

Laser-welded plastic components are becoming increasingly common inside modern vehicles. In the context of the dashboard, in particular, components such as instrument panels and head-up displays are already being laser-welded in many cases. Leister adapts the joining technique to suit the application concerned. The instrument panel shown in the figure is welded using the quasi-simultaneous technique. This is because of its size, which means that component tolerances have to be compensated with a melt path.

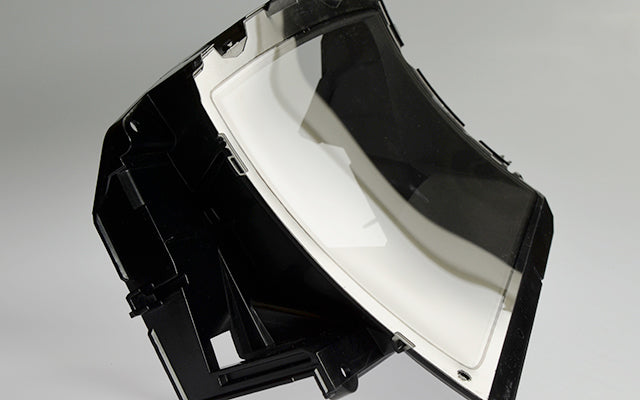

Head-up display

Head-up displays use a thick yet flexible piece of film as an optical element for the purpose of relaying information to the windshield. In this case, the GLOBO welding technique is used, as the low level of heat input prevents the film from being exposed to any stress. In addition, the GLOBO technique is flexible and can be used on various types.

Exterior components in the automotive engineering industry

Taillight

A few exterior components of vehicles are already welded with laser. The car tail-lamp is a typical example for the use of GLOBO welding. The local application of joining pressure during the welding process allows components with three-dimensional joining planes to be welded. The welding seam, which is also of a high visual quality, can also be used as a decorative seam. As well as for vehicle lights, laser welding is also used on other large-volume components. The figure shows a detail image of a sun visor for a truck. The visor has been welded at various points using the GLOBO technique. The detail image shows a welded side window with a camera located behind it.