Roofing

Whether PVC, TPO or Bitumen: Leister Always has the Right Tool on the Roof

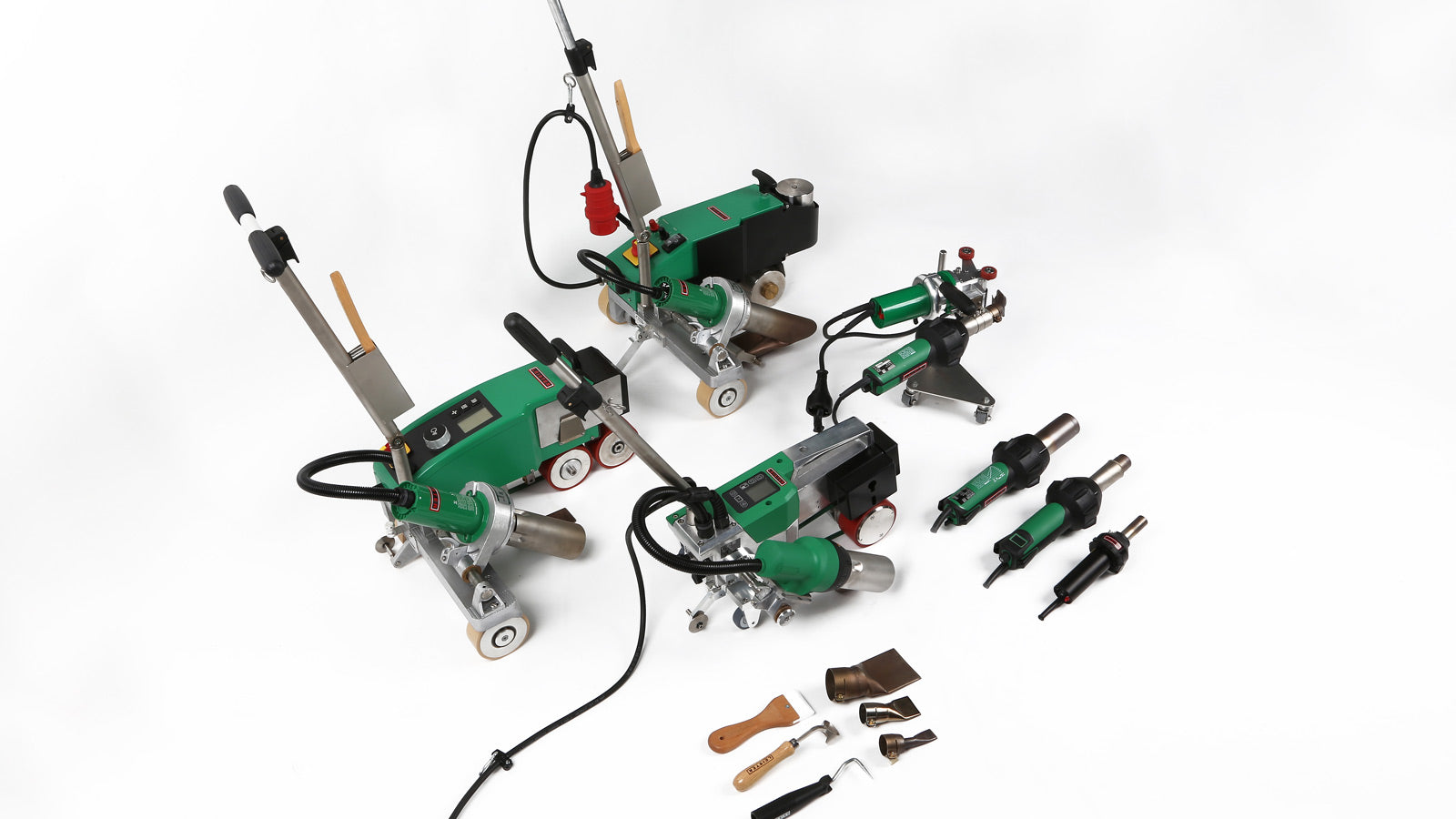

Various materials and systems are available for sealing flat or pitched roofs. The majority of the materials processed to this end around the world consist of thermoplastic membranes (PVC and TPO) or modified bitumen. The individual membranes are usually laid so that they overlap. Leister has the right tools for welding all these materials. Alongside welding machines, a variety of hand welding tools with matching nozzles and devices for testing the welding templates are available for details.

Welding of Single-Ply Membranes on Flat Roofs

Economical and Safe

Leister offers economically-priced and ergonomically-designed hot-air welding machines for the overlap welding of single-ply (PVC, TPO, EPDM, etc) roofing membranes on flat roofs.

- The VARIMAT V2 achieves a unique speed of up to 12 meters (39 feet) per minute. Flat roofs are quickly and safely made leak-tight—thanks to consistent welding parameters which are digitally-monitored and can easily be modified—even in adverse weather conditions.

- The easy-to-handle UNIROOF AT really proves its worth, often in locations which are difficult to access, in the immediate vicinity of walls or on smaller roofs with little room to maneuver.

- The small, TRIAC DRIVE AT semi-automatic welder, is suitable for boarding and channels.

- Before the base seam is actually welded, the seam quality can be assessed using Leister's EXAMO tensiometer.

- Leister offers tried-and-tested handheld welding tools (heat guns) for all precision work—above all the EXAMO — which impress users with their robust design and reliability.

Leister has the solution

Whether for ergonomic, economical welding of thermoplastic single-ply membranes, or heat guns and matching accessories (for working on small roofs, details and in inaccessible locations), Leister has the solution.

- Hot-air welding machines with digitally-controlled technology for reliable welds

- Complete tool range for all applications

- Maximum welding speed

- Long service life with low maintenance requirements

Welding of Sub-Roof Membranes for Pitched Roofs

Reliable and Economical

Leister offers an ergonomic and reliable solution for welding all thermoplastic, single-ply membranes on pitched roofs. The small and flexible hot-air welding machines from Leister make the processing of sheets more economical. The lightweight TRIAC DRIVE AT proves its worth even on the steepest of pitched roofs. The larger, and technologically advanced UNIROOF ST/AT manages pitches of up to 30° with no problem at all. Leister's ergonomically-balanced hand welding tools ensure that work completed in hard-to-access locations does not become tiring.

- Welding of overlap seams on roofs with different pitches

- Prefabrication of sub-roof membranes

- Processing of connections and details

Leister has the solution

Simple and economical welding of sub-roof membranes with Leister's lightweight hot-air welding machines. A wide range of hand welding tools and matching accessories are available for working on details and in inaccessible locations.

- Compact, small hot-air welding machines make the process more economical

- Reliable, lightweight hand welding tools (heat guns)

- Prefabrication makes subsequent laying on the roof easier

- All Leister tools have a long service life and require little maintenance